We Are The Prime Manufacturers!

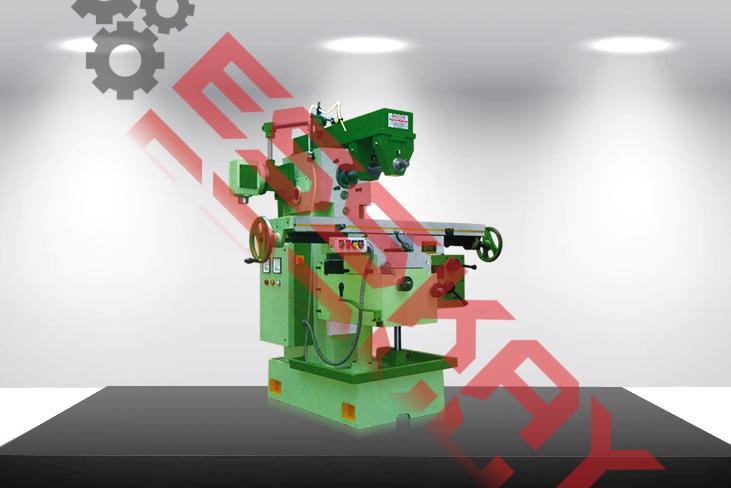

We are a supreme Horizontal Milling Machine Manufacturers, based in India. These machines are manufactured from premium quality raw materials according to the requirements of valuable clients. Our offered assortment of products is sternly checked, examined by the quality experts to maintain the set industrial standards. Our milling machines are ideal for the manufacturing of auto spare parts due to their sturdy construction, anti-corrosive nature, no maintenance and assures maximum productivity in less time with minimum energy consumption. Our offered milling machine is available in various specifications at the most affordable rates.

Since 2008,

Operating in India.

TECHNOLOGY PARTNERS

Our power of choice is untrammelled and when nothing prevents our able to do what we like best every pleasure is to be welcomed and occur that pleasures have to be repudiated.

Contact Us Soon

esskayquery@gmail.com & +91 992-610-2855

Providing High Returns At Low Investment!

Known to give faster operation due to its high spindle speed, our Milling Machine has made our stand among the reliable Horizontal Milling Machinery Suppliers. Apart from this, its high chip cutting capability and user-friendly control operations render easy operation and increased productivity. This Machine is suitable for heavy machining like in power plants, process equipment, pressure vessel components, etc. It comes with well designed suitable attachments like a right angle, universal, boring, and facing. Our provided machines are highly demanded in the market due to their unmatched quality and durability. In addition to this, our offered machines are used to provide perfect shape for different metals.

25+ Years Of Experience

Features Of Our Product

Our product features and applications will give you a better insight into the product!

Features Of Product

Using only the greatest raw materials, we create products that serve a variety of industries.

- Casting body

- Heavy productivity

- Small footprint

- Rigid slide

- Energy efficient

- Bed milling

- Spindle Speed: Pulley drive fix as per requirement by the customer.

- Hardened&ground table surface

- Automatic feed on x, y-axes, motorized table lifting&lowering on the z-axis

- Rapid traverse

- Centralized lubrication system

Applications Of Product

High-quality manufacturing leads to highly efficient products. And such products are helpful in serving varied applications.

- The product is useful for thermal spraying.

- The product is handy for metal spinning.

- Useful for Automobile Industry.

Technical Specification & Accessories

| MODEL | PUM-A | PUM-1 | PUM-1.5 | PUM-2 | PUM-3 | PUM-4 |

|---|---|---|---|---|---|---|

| FACE OF BODY | 7″ | 8.5″ | 10″ | 11″ | 12″ | 13″ |

| SURFACE OF TABLE | 32″8″ | 40″X9″ | 48″X10″ | 52″X11″ | 58″X11″ | 64″X13″3 |

| NO OF T-SLOTS | 3 | 3 | 3 | 3 | 3 | 3 |

| SIZE OF T-SLOTS | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 5/8″ | 5/8″ |

| SWIVEL EITHER SIDE OF SIDE | 45 DEGREE | 45 DEGREE | 45 DEGREE | 45 DEGREE | 45 DEGREE | 45 DEGREE |

| CROSS | 6″ | 7″ | 8″ | 10″ | 12″ | 13″ |

| VERTICAL OF TRAVERSE | 13″ | 15″ | 16″ | 22″ | 24″ | 26″ |

| LONGITUDINAL TRAVERSE | 15″ | 19″ | 22″ | 25″ | 28″ | 30″ |

| STANDARD ARBOUR | 1″ | 1″ | 1″ | 1″ | 1-1/4″ | 1-1/2″ |

| TAPER OF SPINDLE | ISO 30 | ISO 40 | ISO 40 | ISO 40 | ISO 40 | ISO 50 |

| NO. OF SPINDLE SPEED | 3&9 | 9 | 9 | 9 | 9 | 9 |

| DIA OF SPINDLE IN MM | 50 | 70 | 80 | 90 | 100 | 110 |

| NO OF LONGITUDINAL FEED TABLE | 2 | 2 | 3 | 3 | 3 | 3 |

| H.P | 1 H.P | 2 H.P | 2 H.P | 2 H,P | 3 H.P | 3 H.P |

| COOLANT PUMP CAPACITY | 2 GALLONS | 3 GALLONS | 4 GALLONS | 4 GALLONS | 4 GALLONS | 4 GALLONS |

| HEIGHT | 55″ | 62″ | 67′ | 70″ | 73″ | 75″ |

| STANDARD ACCESSORIES |

|---|

| HORIZONTAL HEAD |

| VERTICAL HEAD |

| MOTOR PULLEY |

| OPTIONAL ACCESSORIES |

|---|

| ELECTRIC MOTOR |

| STATER |

| V-BELT |

| MILING VICE |

| RACK CUTTING ATTACHMENT |

| ROTARY TABLE |

| HOBBING ATTACHMENT |

| SLOTTING ATTCHMENT |

| DIVIDING HEAD |

Accomplishing each project with ease in a given time period.

0

+

Project Done

Client first policy has bagged us the recognition we have today!