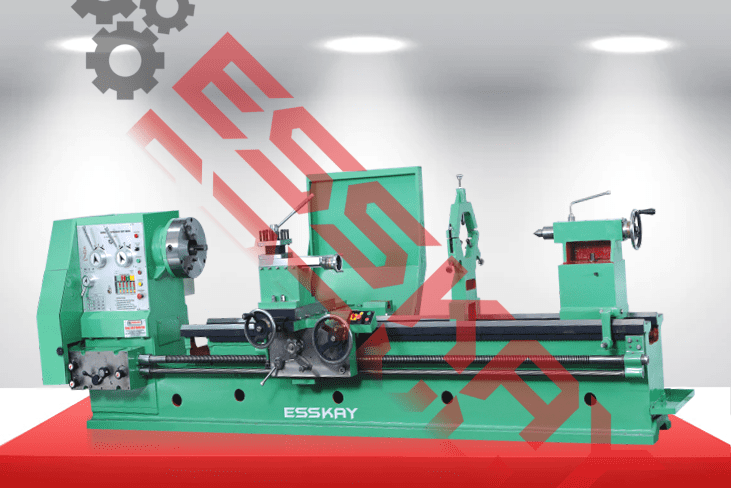

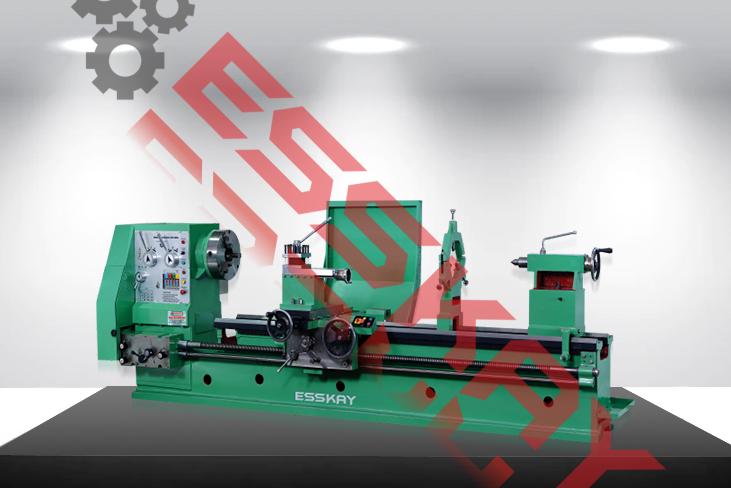

Lathe Machine Manufacturing Process

One of the most popular lathe machine manufacturers in India, it’s our duty to deliver top-quality lathe machines. Our professional team has worked hard on creating a metal lathe machine system that will fulfil your day-to-day operations. We made the machines with high-quality components & latest machinery that is as per industry standard.

Our machines are strongly built and have a long lasting nature. We test these machines on various quality standards before it’s sent to clients. Our customised machines will work easily for the shaping of metal or wood. Buy center lathe machine now and save a lot of funds on them after creating the accurate cylindrical or other different type of shapes.

Since 2008,

Operating in India.

TECHNOLOGY PARTNERS

Our power of choice is untrammelled and when nothing prevents our able to do what we like best every pleasure is to be welcomed and occur that pleasures have to be repudiated.

Contact Us Soon

esskayquery@gmail.com & +91 992-610-2855

The Different Parts & Operation Of Lathe Machine

Being one of the top lathe machine suppliers in India, we constantly strive to deliver quality in our instruments. Our lathe machine is useful in providing you the right shape of your desired material. You can do operations like cutting, turning, knurling, grooving, and sanding with our machines for getting the correct metal shape. The cost of maintenance of our machines is low and will give you higher returns with ease. Our Kharad machine will give you high productivity and reliable performance in extreme situations of work. If you want to do exact shaping jobs, it’s the precise tool for you.

25+ Years Of Experience

Features & Applications

Our product features and applications will give you a better insight into the product!

Features Of Product

Using only the greatest raw materials, we create products that serve a variety of industries.

- Excellent-performance

- High-tensile strength

- Dimensionally accurate

- Corrosive-resistant

- Highly Precise Lathe Work

- Flame Hardened Bed-way

- Bed made of high-quality cast-iron

- The tailstock Spindle is hardened & ground, made from alloy steel

- Gears are made from alloy steel, are hardened & precision-ground

- The apron is an enclosed oil bath system for automatic feeds and gives movements to the saddle

- Headstock spindle made from high tensile steel duly hardened, ground & runs in precision taper roller bearings

Applications Of Product

High-quality manufacturing leads to highly efficient products. And such products are helpful in serving varied applications.

- The product is useful for thermal spraying.

- The product is handy for metal spinning.

- Useful for Automobile Industry.

Accomplishing each project with ease in a given time period.

0

+

Project Done

Client first policy has bagged us the recognition we have today!